With over 30 years of experience, we at M&J Engineering are your metal engineering experts. Whether you require CNC Punching, CNC Folding, MIG & TIG Welding, Edge Rounding and more, we are the company for you. Our friendly and skilled engineers are committed to your 100% satisfaction, so please don’t hesitate to contact us today for a quote on any of our services.

30+ YEARS OF EXPERIENCE

METAL ENGINEERING SPECIALISTS

100% SATISFACTION

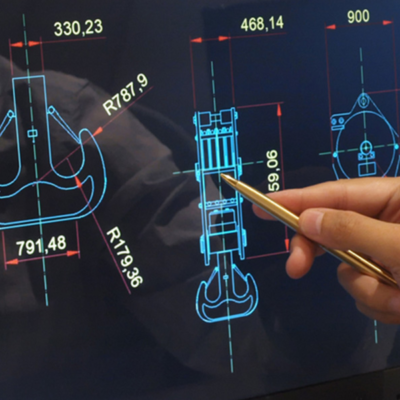

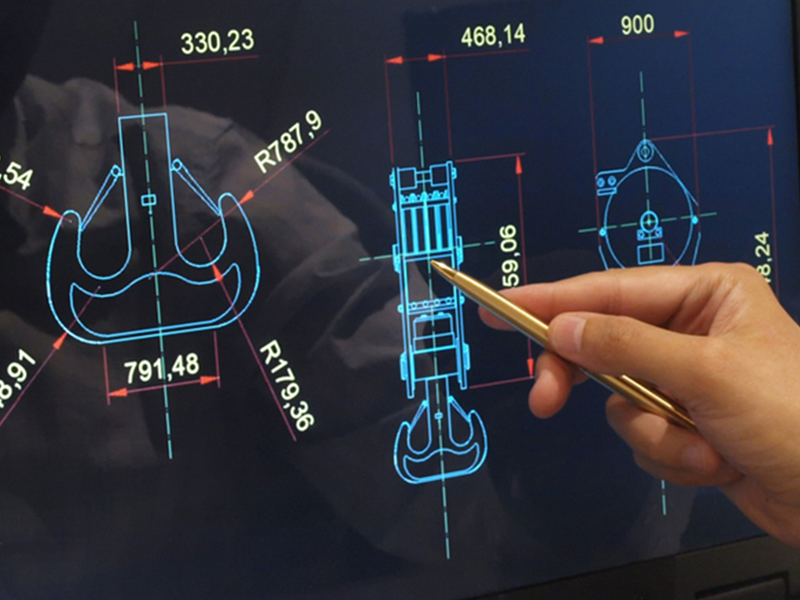

M&J Engineering | 3D CAD & CAM Software

Precision | Accuracy | Speed

At M&J Engineering, we use advanced machinery and software to complete a range of high-quality, finished products to customer specifications. Working with all grades of sheet metal, from mild steel to high-grade stainless and aluminium, we offer efficient and versatile solutions. But how do we ensure such precision, accuracy, and speed? The answer is simple – with our advanced 3D CAD & CAM Software.

What is 3D CAD Software?

3D Computer-Aided Design (CAD) Software designs and prepares 2D drawings and 3D models. Our advanced software can design from scratch or use existing computer files and can import, re-draft and develop your design with DFM (Design For Manufacturability) and MRP (Manufacturing Resource Planning). Our sheet metal software for punching, profiling, bending, design and production management builds accuracy and speed into a project.

What is CAM Software?

Computer-Aided Manufacturing (CAM) automates manufacturing processes using software and computer-controlled machinery. Unlike CAD, which focuses on the design of a product or part and how it functions, CAM focuses on manufacturing it. CAM is the controlled way of changing raw materials into shapes using punching, folding and more. CAM also:

- Checks if the model has any geometry errors.

- Creates coordinates for the machine to follow.

- Sets machine parameters.

- And more!

What can CAD & CAM software help with?

Computer Numerically Controlled Punching, or CNC Punching, is a process used to ‘punch’ shapes into and cut shapes out of sheet metal using a programmable machine. Our advanced computer programming software uses a precise range of coordinates to punch the required shape or patterns into sheet metal. CNC Punching is efficient and cost-effective for small and large batch runs.

What are the benefits of CAD & CAM Software?

Accuracy & Speed

Due to our automation software, our machines are highly accurate. We can effectively decrease production time, irrespective of how complex your design is. Furthermore, precision is guaranteed across the board for quality results.

Productivity

Once a design has been programmed and built, our software retains the pattern, meaning that it can be reused. This increases productivity for any industry as it removes technical and time-consuming manual operations.

Efficiency

Our CAD & CAM software boasts efficiency and can accommodate a range of requirements, from small to large batches. We at M&J Engineering can do whatever you need with our advanced equipment.

Are CAD & CAM software right for my fabrication needs?

If you’re unsure if our software is right for your fabrication needs, speak to our specialist engineers today for more information, we are happy to help.

Need something else?

We also offer a range of other steel fabrication services including:

- Welding

- Fastener Insertion

- Edge Rounding

- CNC Punching

- CNC Folding

- Laser-Cutting

Contact our friendly team today for more information!

Our Satisfied Clients

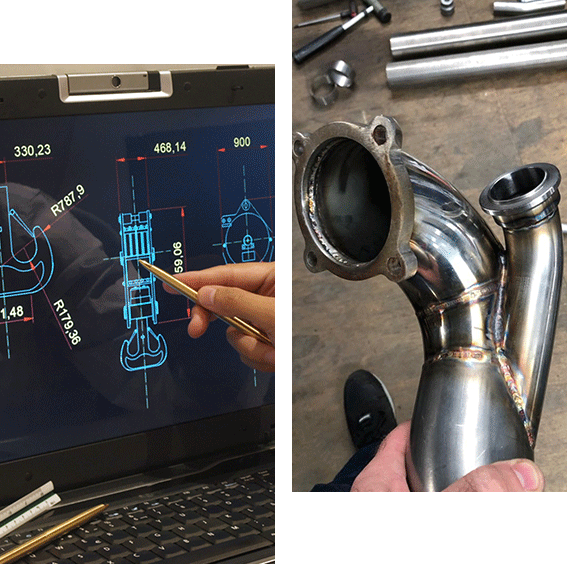

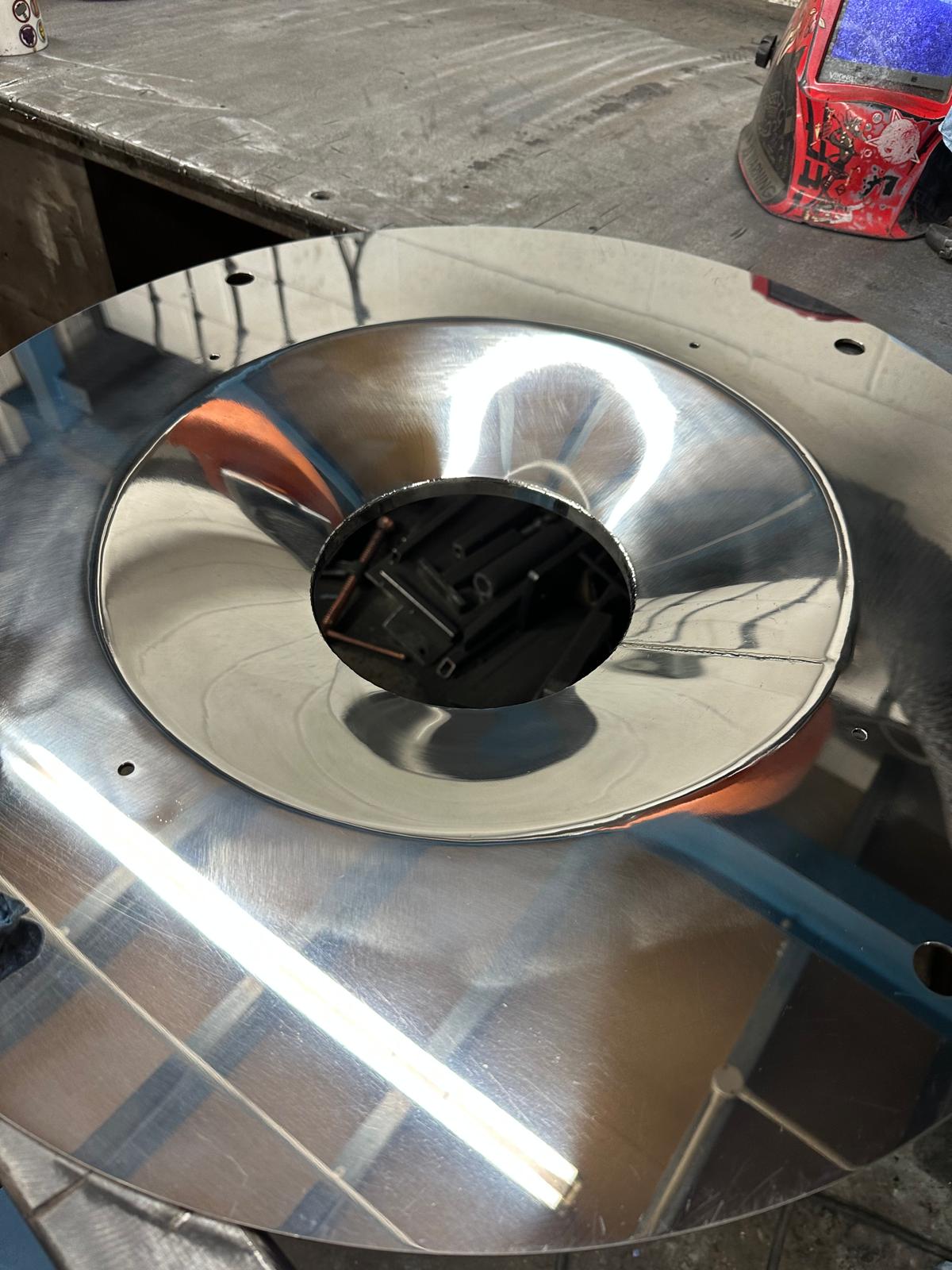

We have worked with clients in a range of industries and have created a versatile selection of products. This includes robotics, vacuum furnaces, electron-beam welders, pollution monitoring equipment, the carbide cutting industry, flat-roofers, industrial printing, and the ventilation industry.

Why work with us?

30+ Years of Experience

With 30+ years of experience in steel fabrication, your requirements will be in safe hands. Whatever you require, we can accommodate it all.

Customer Satisfaction

Your satisfaction is paramount, and we go out of our way to make sure our clients’ standards are always achieved for 100% satisfaction.

Personalised Service

When you come to M&J Engineering, you can enjoy a friendly and personalised service every time that you come to us.

If you’re looking for professional, accurate & cost-effective CAD & CAM Services,

get in touch with us today for a quote!

Our Gallery

Call us today

01353 968267

Contact Information

01353 968267

jon@m-j-engineering.com

M & J Engineering Cambridge

Unit 10 Northfield Business Park Soham,

Cambridgeshire CB7 5UE

Contact us today

Thank you for your interest in requesting a work estimate, please fill out the form and we will get back to you shortly.