With over 30 years of experience, we at M&J Engineering are your metal engineering experts. Whether you require CNC Punching, CNC Folding, CAD & CAM Services, Edge Rounding and more, we are the company for you. Our friendly and skilled engineers are committed to your 100% satisfaction, so please don’t hesitate to contact us today for a quote on any of our services.

30+ YEARS OF EXPERIENCE

METAL ENGINEERING SPECIALISTS

100% SATISFACTION

M&J Engineering | Welding

Our Specialist Welding Solutions

What is welding?

Welding is part of the fabrication process which forms robust joints between two separate pieces of metal. We a range of welding techniques to deliver reliable, durable, and cost-effective solutions.

What types of welding are there?

TIG Welding

Tungsten inert gas (TIG) welding is often used to join a range of small and thin materials. TIG welding uses a non-consumable tungsten electrode to heat the metal and can be used with or without a filler. Though a slower process than MIG welding, TIG welding boasts versatility, precision and accuracy.

MIG Welding

Metal inert gas (MIG) uses a consumable wire that acts as both the electrode and the filler material. In this way, it can be faster than TIG welding, though it is not quite as precise or clean as TIG welding results.

Spot Welding

Spot welding is a resistance welding process that uses an electrical current to join various sheet metal surfaces together. Using the heat obtained from resistance to an electrical current, we can create robust joins between metal materials.

Stud Welding

The process of stud welding involves an arc being ignited between one end of the stud and the metal surface. Both parts are melted and then joined under low-contact pressure. Stud welding can also be used to attach threaded components to sheet metal.

At M&J Engineering we offer welding solutions which can accommodate aluminium, carbon steel, stainless steel and many more. Contact us today for more information about any of our services!

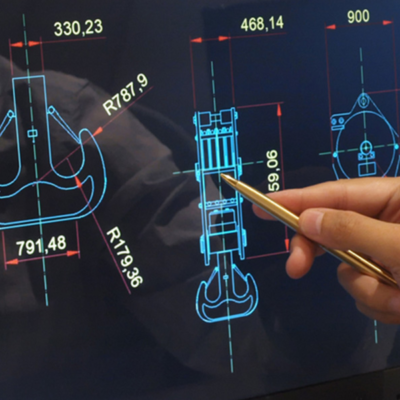

Advanced Equipment

We use top-of-the-range welding equipment to complete our welding processes including two Kemppi Kempact 323R MIG Welders & Kemppi Mastertig MLS 3003 TIG Welders.

How much does welding cost?

The cost of welding will vary depending on several factors. Get in touch with us for a quote.

Is welding right for my fabrication needs?

If you’re unsure if welding is right for your fabrication needs, speak to our specialist engineers today for more information, we are happy to help

Need something else?

We also offer a range of other steel fabrication services including:

- Fastener Insertion

- CAD & CAM Services

- CNC Punching

- Edge Rounding

- Laser-Cutting

Contact our friendly team today for more information!

Our Satisfied Clients

We have worked with clients in a range of industries and have created a versatile selection of products. This includes robotics, vacuum furnaces, electron-beam welders, pollution monitoring equipment, the carbide cutting industry, flat-roofers, industrial printing, and the ventilation industry.

Why work with us?

30+ Years of Experience

With 30+ years of experience in steel fabrication, your requirements will be in safe hands. Whatever you require, we can accommodate it all.

Customer Satisfaction

Your satisfaction is paramount, and we go out of our way to make sure our clients’ standards are always achieved for 100% satisfaction.

Personalised Service

When you come to M&J Engineering, you can enjoy a friendly and personalised service every time that you come to us.

If you’re looking for professional, accurate & cost-effective MIG & TIG welding,

get in touch with us today for a quote!

Our Gallery

Call us today

01353 968267

Contact Information

01353 968267

jon@m-j-engineering.com

M & J Engineering Cambridge

Unit 10 Northfield Business Park Soham,

Cambridgeshire CB7 5UE

Contact us today

Thank you for your interest in requesting a work estimate, please fill out the form and we will get back to you shortly.