With over 30 years of experience, we at M&J Engineering are your metal engineering experts. Whether you require CNC Punching, MIG & TIG Welding, Steel Fabrication or have a last-minute emergency, we have the solutions for you. Our skilled engineers are committed to your 100% satisfaction, so please don’t hesitate to contact us today for CNC Punching, or any of our other quality services.

30+ YEARS OF EXPERIENCE

METAL ENGINEERING SPECIALISTS

100% SATISFACTION

M&J Engineering | CNC Punching

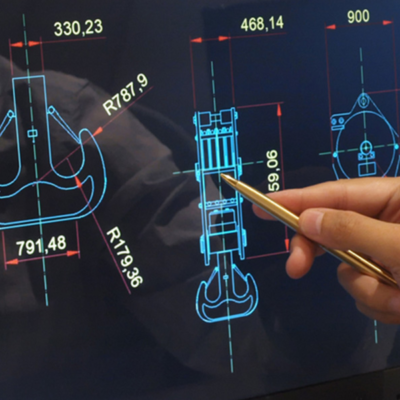

What is CNC Punching?

Computer Numerically Controlled Punching, or CNC Punching, is a process used to ‘punch’ shapes into sheet metal using a programmable machine. With our advanced computer programming software, we use a precise range of coordinates to punch the required shape or patterns into sheet metal. CNC Punching is efficient and cost-effective for small and large batch runs. It can also complete formed features and profiles such as countersinks, beads, and louvres with high accuracy. If you require professional and meticulous CNC Punching, speak to us today for more information.

How does CNC Punching work?

1

Our high-performance programme works using a pattern that has been created in a digital 2D DXF, DWG file format or a 3D format in the Computer Aided Design (CAD) file.

2

This is then used in the Computer Aided Manufacturing (CAM) programme to select the best tool for the job and to fabricate the flat sheet metal component.

3

The CNC nest will then choose the best arrangement for the sheet metal size, delivering accuracy each and every time, regardless of material scale and complexity.

4

The CNC punching machine will then move the sheet metal to place it under the punching ram. This allows the required design to be punched and created with precision.

The benefits of our TRUMPF punching machine…

We have a Trumpf TC3000R large format CNC punching machine complete with TruTops offline programming software and a very large selection of common and special tooling including forming, tapping and wheel technology. Here are some of the benefits that our CNC Punching machinery delivers…

- Geometrically perfect shapes.

- Versatile parts processing.

- Unbeatably fast punching capability.

- High-quality tools from TRUMPF and Wilson Tools.

- Intelligent and safe functions.

What can CNC Punching make?

We work alongside various industries including construction, automotive, architecture, robotics, monitoring solutions and bespoke machinery manufacturers to provide effective and accurate CNC Punching. The range of materials that can be used in CNC machines is extensive and include stainless steel, aluminium, brass, mild steel, molybdenum, plastic and much more. This means that the CNC Punching process is versatile and can accommodate a range of requirements. From the outset, you can experience professional services backed by high-performance machinery and skilled engineers.

How accurate is CNC Punching?

Our CNC Punching machinery is technically capable of punching materials from 0.5mm – 6mm. It also boasts a punching accuracy of 0.02mm.

What are the benefits of CNC Punching?

Accuracy & Speed

Due to the automation software that we use, our CNC Punching machines are highly accurate. We can effectively decrease production time, irrespective of how complex your design is. Furthermore, precision is guaranteed across the board for quality results.

Productivity

Once a design has been programmed and built, our software retains the pattern, meaning that it can be reused. This increases productivity for any industry as it removes technical and time-consuming manual operations.

Efficiency

With our TruTops software we can utilise the nesting facility to minimise material wastage

During the punching process.

Cost-Effective

Our CNC Punching machinery is highly cost-effective as waste is kept to a minimum and very little is thrown away, this means that you will save money in the long run and won’t waste material.

Is CNC Punching right for my fabrication needs?

Achieving precise geometrical shapes with a quality finish is only possible with CNC Punching. Our machinery and advanced programming can deliver fantastic results. If you’re unsure if CNC Punching is right for your fabrication needs, speak to our specialist engineers today for more information, we are happy to help.

How much does CNC Punching cost?

The cost of CNC Punching will vary depending on several factors. Get in touch with us for a quote.

Why work with us?

30+ Years of Experience

With over 30 years of experience in metal engineering, your requirements will be in safe hands. Whether you have a prototype, small or large batch or last-minute emergency – we can do it all.

Customer Satisfaction

Your satisfaction is paramount, and we go out of our way to make sure our clients’ standards are always achieved. Much of our work comes from repeat business or word of mouth which is a testament to our service.

Range of Services

We specialise in prototype, small/large batch work, and production sheet metal engineering including punching, forming, presswork and welded fabrications. Whatever you require, we have the solutions.

If you’re looking for professional, accurate & cost-effective CNC Punching,

get in touch with us today for a quote!

Our Gallery

Call us today

01353 968267

Contact Information

01353 968267

jon@m-j-engineering.com

M & J Engineering Cambridge

Unit 10 Northfield Business Park Soham,

Cambridgeshire CB7 5UE

Contact us today

Thank you for your interest in requesting a work estimate, please fill out the form and we will get back to you shortly.