With over 30 years of experience, we at M&J Engineering are your metal engineering experts. Whether you require CNC Punching, CNC Folding, MIG & TIG Welding, CAD & CAM Services and more, we are the company for you. Our friendly and skilled engineers are committed to your 100% satisfaction, so please don’t hesitate to contact us today for a quote on any of our services.

30+ YEARS OF EXPERIENCE

METAL ENGINEERING SPECIALISTS

100% SATISFACTION

M&J Engineering | Edge Rounding and de-burring

What is edge rounding?

Edge rounding or edge radiusing is the process used to remove burrs, marks or scallops on the edges and holes of a sheet metal part. Edge rounding breaks the edge of a processed component. It does this by creating a radius on the edge of the metalwork to remove the sharpness of the edge and deliver a uniform and clean rounding. We strongly recommend edge rounding on all of our client’s laser-cut components.

Why is edge rounding important?

Improves Safety

Edge rounding ensures that the metalwork is safe for employees and end-users. A machined piece that contains burrs is flawed, therefore compromising the safety of those who use it.

Accuracy

Edge rounding machinery works to remove imperfections that could compromise the finished product. By removing all burrs, you can ensure that each part is completed to specifications and will work properly for its intended application.

Aesthetics

The presence of burrs leaves rough ridges and sharp edges which are unappealing to the eye. Edge rounding delivers a uniform and clean finish to the metalwork.

Paint Adhesion

If your part or metalwork is going to be painted on, there must be no rough or sharp edges. If there are, the paint will not adhere to the steel and will flake off, this could lead to corrosion over time.

How much does edge rounding cost?

The cost of edge rounding will vary depending on several factors. Get in touch with us for a quote.

Our Advanced Machinery…

Using our high-performance 32 RB Series Rotary Brush Machine, we can offer versatility for edge rounding. This means that we can produce high-quality, finished products to customer specifications every time.

If you are a Laser Cutting or Water Jet Cutting company, why not

get in touch with us today to see how our Edge Rounding services could benefit you?

We also offer deburring by hand where required…

Deburring is a reliable way of removing burrs to produce smooth, quality components. Using professional tools and techniques, we can manually remove the burrs to leave the metalwork smooth. Get in touch with us for more information about deburring.

Need something else?

We also offer a range of other steel fabrication services including:

- Welding

- Fastener Insertion

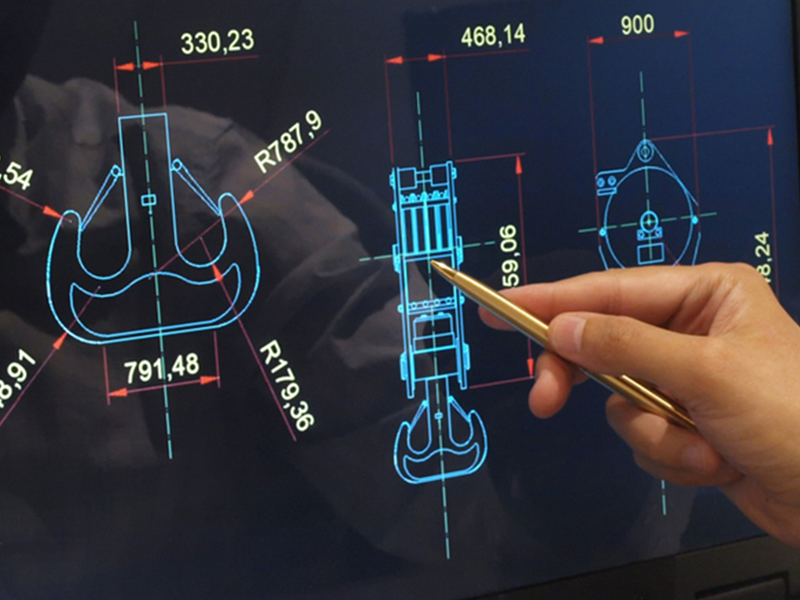

- 3D Cad & Cam Software

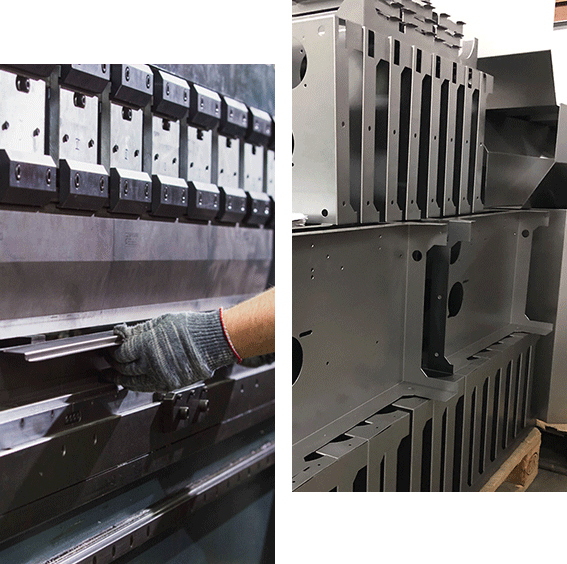

- CNC Punching

- CNC Folding

- Laser-Cutting

Speak to us today for more information about Edge Rounding or any of our quality services!

Our Satisfied Clients

We have worked with clients in a range of industries and have created a versatile selection of products. This includes robotics, vacuum furnaces, electron-beam welders, pollution monitoring equipment, the carbide cutting industry, flat-roofers, industrial printing, and the ventilation industry.

Why work with us?

30+ Years of Experience

With 30+ years of experience in steel fabrication, your requirements will be in safe hands. Whatever you require, we can accommodate it all.

Customer Satisfaction

Your satisfaction is paramount, and we go out of our way to make sure our clients’ standards are always achieved for 100% satisfaction.

Personalised Service

When you come to M&J Engineering, you can enjoy a friendly and personalised service every time that you come to us.

If you’re looking for professional, accurate & cost-effective Edge Rounding services,

get in touch with us today for a quote!

Our Gallery

Call us today

01353 968267

Contact Information

01353 968267

jon@m-j-engineering.com

M & J Engineering Cambridge

Unit 10 Northfield Business Park Soham,

Cambridgeshire CB7 5UE

Contact us today

Thank you for your interest in requesting a work estimate, please fill out the form and we will get back to you shortly.