If you’re a business which has a large number of parts lying around your factory, shop, or anywhere else, you’ll know how difficult it can sometimes be to identify and locate the particular part that you need. One sheet of metal can look very similar to another, yet getting them mixed up can sometimes have serious consequences.

That’s why it’s so important that you can correctly identify any part quickly, and one of the best ways of doing this is by making a permanent mark on each part that is easy to distinguish.

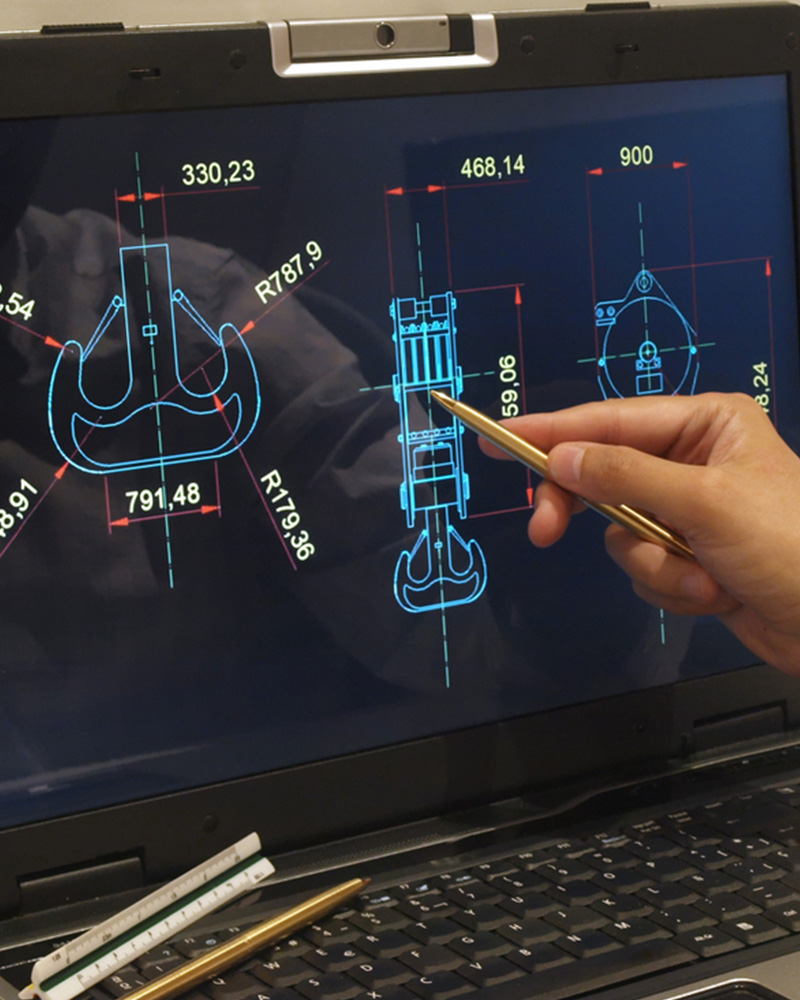

CNC punching is the perfect way for you to do this. Faster, safer and more cost effective than manual pressing, CNC punches provide a means of always being able to identify any thin material that you need.

If you’re interested in finding out more about CNC punching Haverhill, or if you want to find out more about our fast CNC punching service, get in touch with us today.